Aluminum Extrusion Process at Viet Y Industrial Aluminum Factory

In the field of aluminum profile manufacturing, the extrusion process plays a key role in determining the quality, precision, and stability of the final product.

At Viet Y Industrial Aluminum Joint Stock Company, we operate a fully synchronized extrusion line with advanced technology and a strictly controlled process. This allows us to produce high-standard aluminum profiles that meet the stringent requirements of both domestic and international markets.

Overview of the Aluminum Extrusion Process

Aluminum extrusion is a manufacturing technology in which heated aluminum billets are forced through a pre-designed die using extreme hydraulic pressure. Once the aluminum exits the die, it takes the desired shape—such as box, U, T, I, grooved bar, round, or elliptical profiles—depending on the application.

At Viet Y Industrial Aluminum Factory, this process goes beyond mere production. It is integrated with surface treatment steps, quality inspection, and product finishing tailored to customer requirements.

7 Detailed Steps in the Aluminum Extrusion Process at Viet Y Industrial Aluminum

Step 1: Selecting and Preparing Aluminum Billets

Viet Y uses high-quality alloy billets such as 6063, 6061, 6005… sourced from reputable suppliers or produced according to international standards. Prior to processing, the billets undergo chemical composition and mechanical property testing to ensure suitability for the intended use.

Step 2: Preheating the Aluminum Billets

The billets are heated in a furnace to a temperature of 450°C – 500°C to achieve optimal plasticity for extrusion. This stage is automatically monitored by temperature sensors to preserve the material’s internal structure.

Step 3: Extrusion Through Shaping Dies

The heated billets are placed into the extrusion chamber. A powerful hydraulic press (1,000 – 2,800 tons) pushes the aluminum through a precision-engineered die designed with CAD/CAM technology. The result is a precisely shaped aluminum profile with sharp and consistent details.

Step 4: Cooling the Aluminum Profiles

After exiting the die, the aluminum profiles are immediately cooled using high-powered air fans or water mist spray. Rapid cooling stabilizes the material structure and reduces warping.

Step 5: Stretching and Straightening

The profiles are stretched using specialized machinery to eliminate residual stress, ensuring straightness, mechanical strength, and dimensional stability.

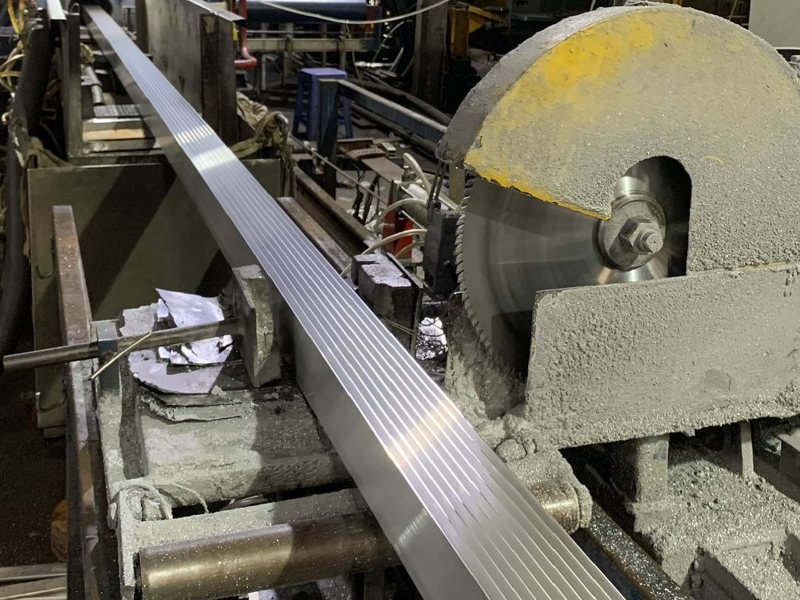

Step 6: Cutting to Standard or Custom Lengths

The aluminum profiles are cut by automated machines to standard lengths (6m, 5.8m…) or custom dimensions based on customer requirements. All profiles are inspected for dimensional accuracy before proceeding.

Step 7: Heat Treatment and Surface Finishing

Depending on the intended use, products may undergo aging (hardening), anodizing, powder coating, chrome plating, etc., to enhance durability, corrosion resistance, and visual appeal.

Key Advantages of the Extrusion Process at Viet Y Industrial Aluminum

- Precision in Every Detail: In-house die manufacturing optimized with Moldflow software ensures ideal material flow and superior profile quality.

- Modern, Synchronized Production Line: Extrusion presses, CNC cutters, stretchers, and surface treatment systems are carefully invested in from Europe and Japan.

- High-Quality Finished Products: Smooth, uniform surfaces; high dimensional accuracy; ISO-compliant and export-ready.

- Flexible, Customized Production: We offer design and machining services based on technical drawings or actual samples, with no limit on shape or quantity.

Address of Viet Y Industrial Aluminum Joint Stock Company

Address: Lot CN04, Dong Van I Expanded Industrial Park, Bach Thuong Ward, Duy Tien Town, Ha Nam Province, Vietnam.

Hotline: 0904217729 | Email: aluminiumvietyjsc@gmail.com

Danh mục sản phẩm

Tin tức nổi bật

Video mới

YÊU CẦU BÁO GIÁ

Xem ý kiến khách hàng

Thống kê

Ngày:

Ngày:  Tuần:

Tuần:  Tháng:

Tháng:  Năm:

Năm:  Online:

Online: